Customer Service in Manufacturing: Why CXOs Must Lead the Modernization

Customer service in manufacturing is increasingly becoming the differentiator. In today’s hyper-competitive world, products no longer differentiate brands — customer service does.

For manufacturers of appliances and industrial products, where equipment is installed on-site and serviced over years, delivering excellent after-sales service is a strategic advantage.

Yet, many manufacturers still rely on spreadsheets, emails, and legacy systems that create silos and slow response times. In this guide, we explore how modernizing customer service leads to stronger retention, better cost control, and happier customers — and why CXOs must lead this shift.

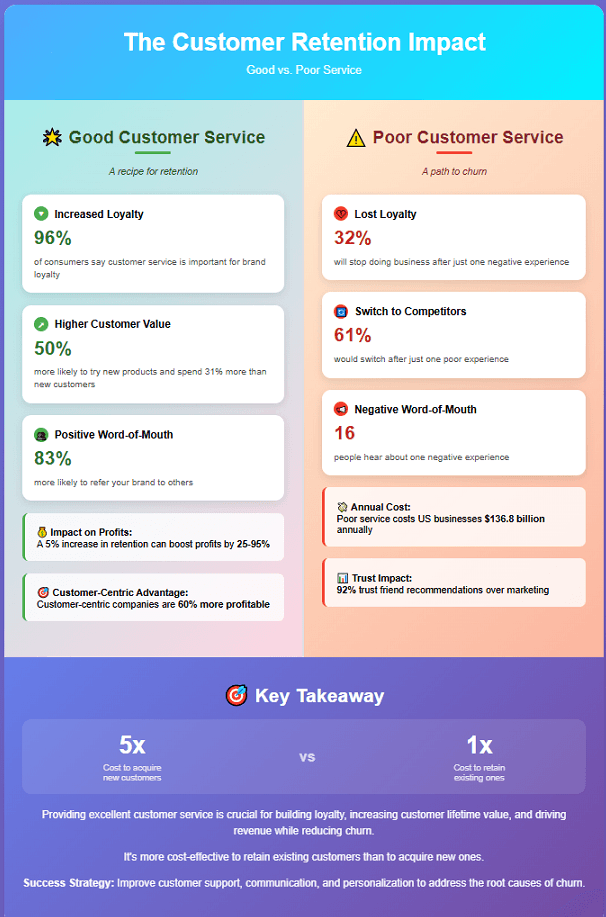

How Customer Experience Drives Retention and Cost Savings

Manufacturers have long focused on product performance and distribution, often treating service as a cost center. But that’s changing rapidly. We put together an infographic on exactly how relevant customer service is in building customer loyalty.

Today, post-sales service is the key to customer retention. When equipment breaks down or needs maintenance, the speed, clarity, and professionalism of your support team become the customer’s entire brand experience.

- 70% of customers say service experience influences repurchase decisions

- Poor service leads to churn, even when the product itself is excellent

- Repeat service visits, miscommunication, or delayed responses inflate costs

And it’s not just about satisfaction — it’s about margins. Manufacturers who manage field service well:

- Resolve tickets faster

- Reduce technician visits

- Minimize unplanned downtime for customers

In short, customer experience in manufacturing directly impacts both revenue and cost efficiency.

Customer Service in Manufacturing: Why Legacy Tools Slow You Down

Many manufacturing companies still use a patchwork of tools: Excel sheets, email chains, and CRMs not built for field teams.

Common issues:

- No real-time visibility into technician availability

- Manual dispatching and tracking delays responses

- Unable to fix accountability or establish audit trail of activities.

- No tracking of spare parts and consumables and availability at any level.

- Missing customer self-service.

These tools weren’t designed for field-heavy service models. As your service network grows, inefficiencies multiply. Costs rise, customers get frustrated, and CXOs end up firefighting.

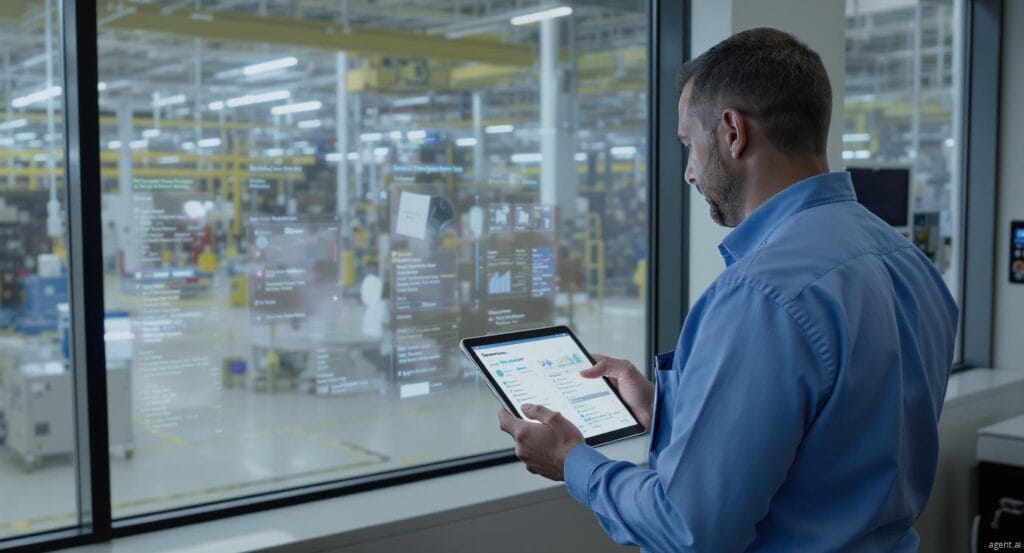

A Digital Service Blueprint for Manufacturers

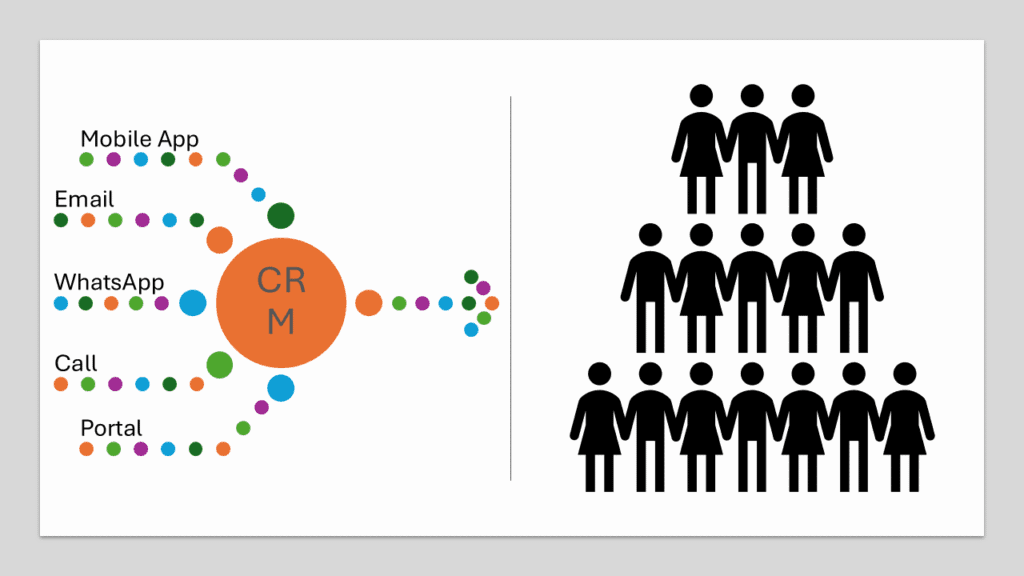

Modern customer service in manufacturing needs more than a CRM — it needs a connected platform built for service workflows.

Here’s what leading manufacturers implement:

Centralized Ticketing

Unify service requests from all channels: Email, WhatsApp, Portal, Call centre- with prompt acknowledgement. Give your customers the freedom and the assurance of prompt action.

Field Team Coordination

Assign the right technician with real-time scheduling, check-ins, and service history. Divide up the geographical territory and assign to teams and hierarchies and auto-assign tickets based on pre-assigned rules.

Deliver Customer Service in Manufacturing in partnership with customers

Let customers raise requests, upload photos, and track progress independently. Provide a mobile app interface for ultimate flexibility. A customer service portal is where your customers gain visibility and control over the customer service process.

The biggest bottleneck in delivering customer service in manufacturing is registering complaints by customers. The customers need a fast and convenient experience. Sadly, many times call centres are not good enough to provide the experience. Especially when multiple languages are needed to address a customer base.

Your customers are in spread-out geographies and timezones. So, rather than keeping your call center open 24/ 7, you should direct your customers to a self-service portal or a mobile app to log tickets directly.

Tracking expenses towards parts and consumables

The highest cost component of customer service in manufacturing are towards spare parts and consumables. This is also an area that the customers want transparency.

You want to ensure:

- Right parts are used in the right repair

- Genuine spare parts from the company stock is used.

- The correct price is charged for the parts.

Also, the spare parts and consumables are expensive. Hence, you should be able to check stock availability of it at all times.

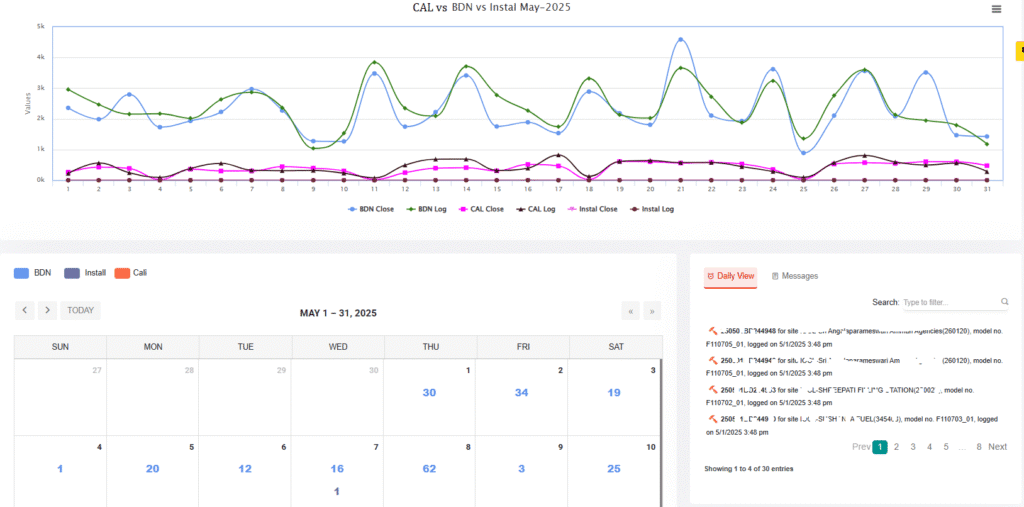

Analytics and Reports: Customer Service in Manufacturing

Monitor KPIs like resolution time, first-time fix rate, and technician performance. Monitor the key metrics in a graphical dashboard. Your analytics and reports must help monitor progress, take action and improve.

Hosting Flexibility

Deploy on your own infrastructure or in the cloud — your data, your control.

While the global trend is definitely towards the public cloud, many customers still want to keep their data under tight control. And hence, they want to self-host their customer service software.

Introducing a Unified Platform for Field Teams and Customers

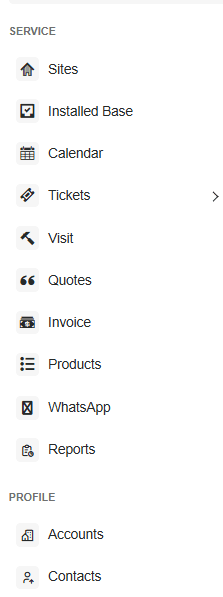

SimplyC2 is for manufacturers with large installed equipment bases, field service teams, and strict customer expectations.

It offers:

- Real-time ticket tracking and technician assignment

- Customer-facing self-service portal

- Spare parts usage tracking and stock taking

- Intelligent SLA tracking and escalation workflows

- On-premise or cloud deployment options

SimplyC2 helps teams move from reactive to proactive service. While, it gives CXOs the visibility and control they need to drive impact.